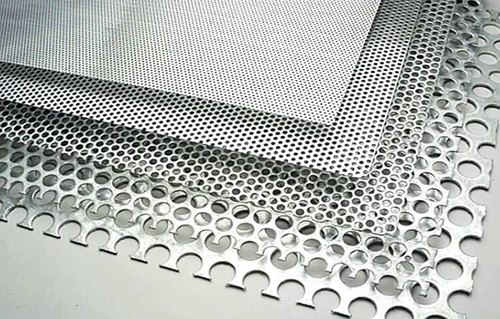

Gayatri Tube is one of India’s driving producers of first-rate Stainless Steel Perforated Sheets that track down applications across various regions. We stock these penetrated sheets in various measures and model sizes. These are astonishing in strength and delivered utilizing incredible solidified steel. It is used in diverts of start engines in vehicles, ventilation of food grain station, and security of rooms from the sound. We offer these sheets in different grades like SS 304 Perforated Sheets, SS 310 Perforated Sheets, SS 316 Perforated Sheets, SS 316L Perforated Sheets and that is only the start. Our SS Perforated Sheets can be introduced in extraordinarily made length sizes and shapes, and are available at market driving expenses An opening of material is accomplished by using mechanical means to enter, or “punch”, through the material surface, leaving behind an opening of explicit size and shape. All things considered, penetrated material routinely involves level sheets that are changed by making rehashing instances of punched shapes.

Execution of penetrated things into any errand requires data on the cost ideas connected with express metal arrangements. It is fundamental to get the various traits of a sheet and the decisions available while deciding the thing to be made. Before mentioning extraordinarily penetrated sheets, the buyer ought to usually decide these three qualities:

1. Material Type and Thickness

There are numerous sorts of materials fitting for penetrating, with what is by and large appropriate for the specific exercises subject to the material cost and properties. Routinely elaborate materials for Penetrated metal is:

• Hot-rolled and cold-moved carbon steel

• Energized Steel, ordinarily pre-blended (charges prior to punching)

• Tempered steel (Type 304 and 316, the two standard and low carbon groupings)

• Aluminum

• Metal Copper

Material thickness is in like manner basic to consider, especially since the cost of made pieces is regularly gotten from the “per pound” cost of the material, and penetrated pieces are no extraordinary case. The thinner the penetrated sheets, the less material used to make the finished piece, and subsequently the lower the expense per piece.

As well as essentially getting a good deal on material cost, it is less difficult for shops to punch and work thin(ner) sheets than it is to machine thicker pieces, which makes related venture supports in progress expenses as well. It is basic to recall, regardless, that decreasing the cross-section of the sheets by picking a lesser thickness will make a diminishing in the fundamental furthest reaches of the sheet.

The use of higher-strength pieces can, occasionally, achieve an overall reduction in the number of pieces that are required. The organizer ought to change material thickness versus essential requirements to finally choose the best method for achieving a cost useful endeavor.

2. Opening Shape and Size:

Penetrated thing creators can make a wide show of opening shapes and models in material sheets utilizing standard and custom punches, motorized punching configuration projects, and uncommon assembling techniques. Such opening shapes available in penetrated things are limited solely by the mechanical ability to machine the cutting passes on into a specific game plan that can make the shape, yet get through the weights of the punching framework. A roundabout opening is a most un-requesting and most moderate shape to solidify into a penetrated sheet, as the general ease of machining a round piece achieves low gathering costs.

Opening still hanging out thereby drawing a circle around the initial shape with a scope that loosens up from the point of convergence of the shape as far as possible external edge. Routinely the initial size is more important than or identical to the thickness of the material being punched, all around, significantly more unmistakable. For high-strength material, for instance, treated steel, the initial size ought to generally be something like 2 to numerous times the thickness of the metal sheet to give a flawless and clean, easier gathering, and reasonable cost.

3. Edges

The end edge width on penetrated sheets is usually zero, and that truly means that there is no distance between the penetrated models and the completion of the sheet. This is known as a “deficient model” and occurs while the punching continues to the completion of the sheet and the openings don’t complete their last cut flawlessly inside the sheet borders. Stock sheets are most commonly available in an inadequate model plan. It is furthermore the most reasonable strategy for assembling a piece without any planning. At the point when needed, a base edge width can be made on the completion, yet anticipate that acclimations should the opening cycle, achieving all the more expensive sheets.

Treated Steel Grades

We’re glad to make punctured items utilizing treated steel. Allowing us to source the material recoveries you time and bother, liberating you to zero in on your center business. Our specialists can deal with a variety of hardened steel types.

Austenitic Stainless Steel – Contain a high level of nickel and chromium which improve its capacity to be welded into any shape while giving protection from consumption and extraordinary strength.

Ferritic Stainless Steel – These are non-attractive non-heat-treatable prepares that have great hotness and erosion opposition and are not solidified by heat treatment, yet are possibly hardenable by chilly rolling.

Duplex Stainless Steel – These are about two times as solid as standard austenitic or ferritic treated steels. They are very consumption safe which is credited to their compound structure and adjusted microstructure.

Martensitic Stainless Steel – Possess high consumption obstruction and its hardness levels are among the most noteworthy of the relative multitude of tempered steels. These grades are attractive and can be solidified by heat treatment.

Get more to know Criteria Involved in Manufacturing Perforated Sheets Knowing the particular judgments of your penetrated thing can help with accelerating the undertaking’s satisfaction and lets you know what the future holds in regards to cost and course of occasions. To learn about the components that go into picking your thing, download our new eBook, Proper Selection for Perforated Products.